Have you ever wondered how 3D models are created for 3D printing? It’s a fascinating process that requires precision, creativity, and technical knowledge. In this blog post, we’ll take you behind the scenes and show you the step-by-step process behind designing a 3D model for 3D printing.

From ideation to modeling to finalising the design, we’ll explore each stage in detail and provide tips and tricks along the way. Whether you’re a novice or an experienced 3D designer, you’ll find valuable insights and inspiration in this post.

So, let’s dive in and discover how to create amazing 3D models for 3D printing!

Designing a 3D model for manufacturing involves several key steps to ensure that the design is suitable for production. Here’s a general overview of the process:

- Define the Design Requirements: Begin by clearly defining the requirements and specifications for your product. Consider factors such as size, functionality, materials, tolerances, and production volume. This will help guide the design process and ensure that the model meets your manufacturing needs.

- Conceptualize and Sketch: Start by sketching rough ideas and concepts for your product. This helps visualize your design and explore different possibilities. Consider the form, function, and overall aesthetics of the product during this stage.

- Create a 3D Model: Once you have a clear concept in mind, use 3D modeling software to create a digital representation of your product. Popular software options include Autodesk Fusion 360, SolidWorks, or Blender. Design the model by creating and manipulating 3D shapes, adding features, and refining the details.

- Consider Manufacturing Constraints: During the design process, keep in mind the constraints and limitations of the manufacturing process you plan to use. Understand the capabilities of the chosen manufacturing method, such as injection molding, CNC machining, or additive manufacturing (3D printing). Consider factors like draft angles, wall thickness, undercuts, and support structures.

- Perform Design Analysis: Utilize the tools available in your 3D modeling software to perform design analysis. Check for potential issues like interference, stress concentrations, or weak points. This step helps identify and address design flaws before moving forward with manufacturing.

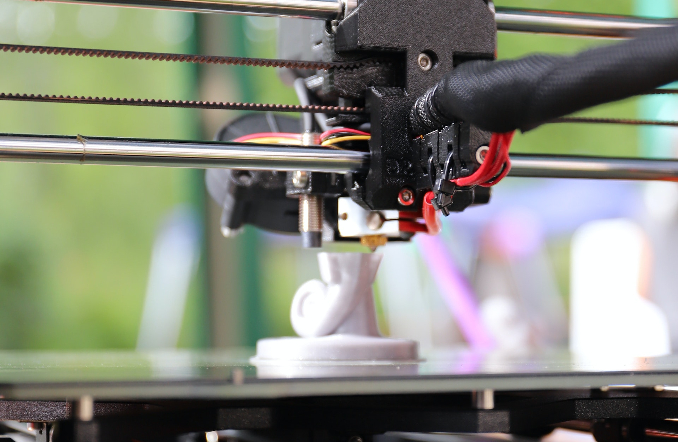

- Prototype and Test: Create a physical prototype of your design using rapid prototyping techniques or other cost-effective methods. This allows you to evaluate the functionality, ergonomics, and overall performance of your product. Test the prototype to ensure it meets your requirements and make any necessary design iterations.

- Prepare Technical Documentation: Generate technical drawings and specifications that clearly communicate the details of your design to manufacturers. Include dimensions, tolerances, material specifications, and assembly instructions. These documents serve as a guide for manufacturing your product.

- Choose a Manufacturing Method: Based on your design requirements, budget, and production volume, select the most appropriate manufacturing method. Work closely with manufacturers or production experts to ensure that your design is compatible with the chosen manufacturing process.

Remember, the specific steps and considerations may vary depending on the complexity of your product and the manufacturing processes involved. It’s often beneficial to consult with experienced engineers or designers who specialise in product development to ensure a successful transition from design to manufacturing.